Business View

The following page offers a high level business view on the Traceability KIT with its vision, mission, benefits, business value, customer journey and examples in form of videos.

Vision & Mission

Vision

The aim of the Traceability KIT is to trace parts and materials across the entire value chain to enable data driven use cases over all n-tier levels without compromising data sovereignty. This KIT enables data and app providers to deliver solutions for building data chains and to send quality notifications on all levels and industries.

Mission

The Traceability KIT provides the necessary standards, aspect models, APIs, logics, and processes on how to build a data sovereign data chain and send quality notifications. This is done via the standardized creation of digital twins of components and vehicles as well as the logical linking to their sub-components (Bill of Material, BoM). The default visibility of digital twins and their respective semantic models follows the one-up/one-down principle. This enables businesses to track and trace products, components, material, and software along the value chain for all product lifecycle stages.

All described specifications in the KIT are based on Catena-X standards like Data Space Connector, Asset Administration Shell (AAS), and Digital Twin Registry (DTR). They refer to other Catena-X KITs like the Connector KIT (EDC), Data Chain KIT (Item Relation Ship, IRS) and Business Partner KIT to ensure interoperability and data sovereignty according to IDSA and Gaia-X principles.

Furthermore, APIs and data models enable partners to send quality notifications in a standardized way while already knowing which parts of their direct customer and suppliers are affected and which are not. Moreover, the KIT is compatible with the data chain KIT to allow apps and business to traverse through the data chains over n-tier levels to enable further use cases like Circular Economy.

In the current version, the KIT supports the creation of data chains for the life cycle contexts “as built” and “as planned”. Further lifecycle contexts, e.g., as maintained will be supported in the future. Overall, the KIT represents the backbone to build data chains for use cases based on vehicles and parts. It empowers app providers to develop a Catena-X Traceability application and data provider to implement their digital twins and the connection to their subcomponents themselves.

Business Value & Benefits

Business Value

Through the standardized specifications described in the “Traceability-KIT” – for example the semantic models and APIs – application and service providers can reduce investment and implementation costs to integrate new Catena-X services. Furthermore, application and service providers can enter potential new markets within the PLM & Quality domain. Data Provider and Businesses are able to build data sovereign data chains to enable data driven use – also for other domains like sustainability.

Todays Challenge

From Traceability's perspective, the main challenge within the automotive industry is to define and implement inter-organizational end-to-end data chains across the whole automotive supply chain to empower data driven use cases. Details regarding the challenges are:

Missing standards to trace serialized and non-serialized hardware and software components. This includes the datatype, data format and data description (semantics) as well as the data exchange. The existing regulatory requirements that every company within the industry faces today are being solved with individual, proprietary solutions.

The digital maturity is diverging within the automotive industry. For bigger companies it is a challenge to receive overall structured data from multiple different suppliers on a broad scale. Smaller companies struggle to generate and provide those data in a fully digitized way.

Current solutions are either costly due to expensive distributed ledgers or cannot guarantee trust and data sovereignty based on the GAIA-X and IDSA principles including the regulation of access and usage policies regarding data chains. Therefore, no end-to-end data exchange and cooperation has been achieved as of today.

Benefits for OEM, SME and Solution Provider

OEM

For OEM and large automotive suppliers: The Traceability solution from Catena-X enables companies to identify products affected by a defect faster and more precisely and thus avoiding general and inaccurate recalls. Through this targeted containment, companies can save both time and money with fewer actions for their customers. Moreover, the Traceability solution enables businesses to rapidly identify the affected part and the corresponding supplier after receiving an alert from the customer. This leads to faster and, therefore, cheaper problem-solving for all parties and less complicated claim management. Furthermore, suppliers can prove compliance of their supply chain to upcoming regulations such as the Supply Chain Act.

SME

The developed and simple-to-use Traceability solutions support SMEs in their mission to digitize the shop floor and communication with customers and suppliers. Today, in order to provide data to their customers and suppliers, SMEs are obligated to use several, proprietary B2B-interfaces from their customers. With Catena-X aiming to have only one digital interface for all customers and suppliers, it increases the ease of data exchange and saves IT resources. Furthermore, due to the Catena-X data sovereignty principles, all participants know what happens with their data. This increases trust in the data exchange.

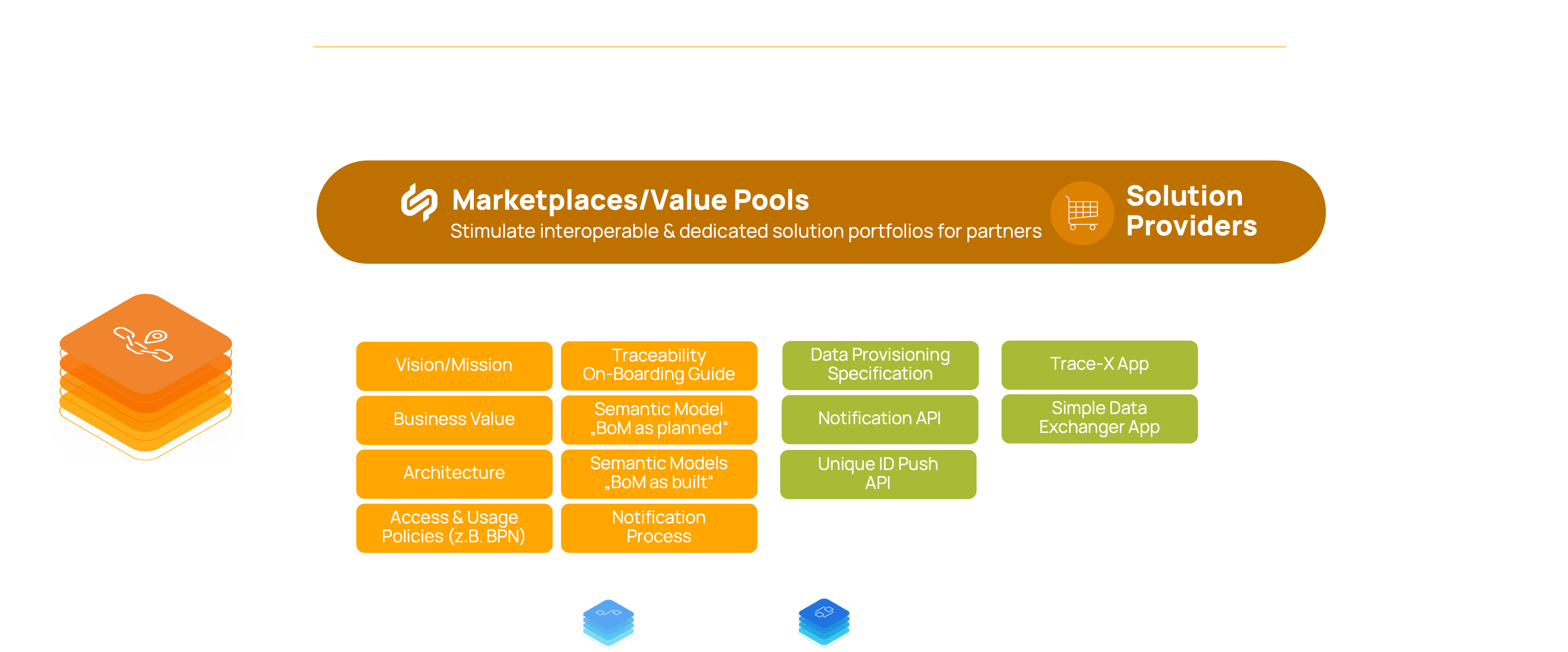

Solution Provider

Solution providers have the potential to scale customer groups and access new market potentials via marketplace and shared service network.

Customer Journey

With the Traceability KIT, we support the Catena-X customer journey for our adopters and solutions providers.

Further Explanations

Example - Industry Problem

The KIT enables business to start Quality Investigations and send Quality Alerts in a standardized way while already knowing which parts of your direct customer and suppliers are affected and which are not.

Through the introduction of unique Catena-X IDs, companies can register digital twins for vehicles, products, components, and raw materials and uniquely identify them within the whole Catena-X ecosystem. Building on that, it is possible to interconnect the registered digital twins of different companies to create a coherent automotive data chain from end-to-end. Furthermore, those twins can easily be complemented with further data like material information to enable further use cases like Circular Economy.

Video

The following video gives an overview of the presented Traceability Use Case.

NOTICE

This work is licensed under the CC-BY-4.0.

- SPDX-License-Identifier: CC-BY-4.0

- SPDX-FileCopyrightText: 2023 BASF SE

- SPDX-FileCopyrightText: 2023 Bayerische Motoren Werke Aktiengesellschaft (BMW AG)

- SPDX-FileCopyrightText: 2023 Fraunhofer-Gesellschaft zur Foerderung der angewandten Forschung e.V. (represented by Fraunhofer ISST & Fraunhofer IML)

- SPDX-FileCopyrightText: 2023 German Edge Cloud GmbH & Co. KG

- SPDX-FileCopyrightText: 2023 Mercedes Benz AG

- SPDX-FileCopyrightText: 2023 Robert Bosch Manufacturing Solutions GmbH

- SPDX-FileCopyrightText: 2023 SAP SE

- SPDX-FileCopyrightText: 2023 Siemens AG

- SPDX-FileCopyrightText: 2023 T-Systems International GmbH

- SPDX-FileCopyrightText: 2023 ZF Friedrichshafen AG

- SPDX-FileCopyrightText: 2023 Contributors to the Eclipse Foundation

- Source URL: https://github.com/eclipse-tractusx/eclipse-tractusx.github.io/tree/main/docs-kits/kits/Traceability%20Kit (latest version)